Bend Radius For 2mm Sheet Metal

It is possible to choose other bends if you require but additional lead time and tooling charges may apply.

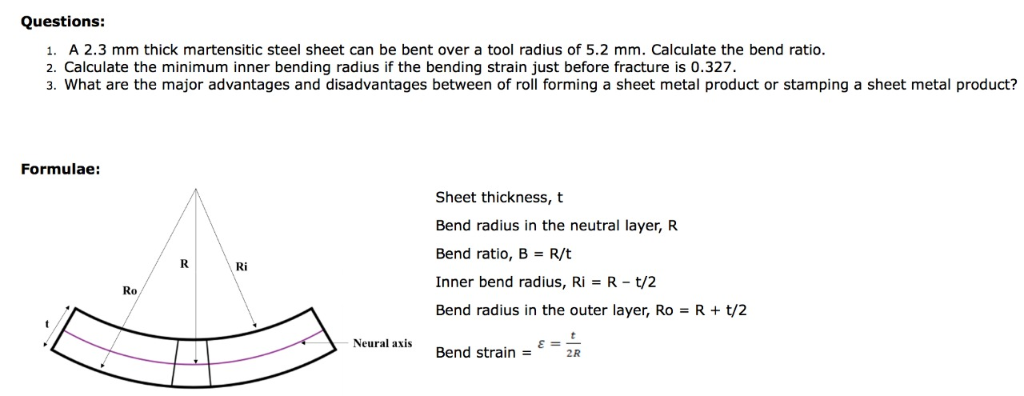

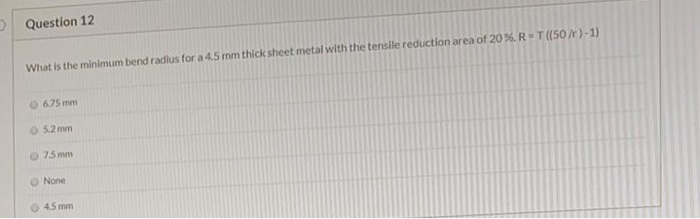

Bend radius for 2mm sheet metal. Discover all our calculation tools in the calculators section of the top menu. We are going to review three bending scenarios with three different bending angles. The required die width is 12 mm and tonnage per meter is 22. If the bending radius is too small it will cause cracking at the bend position.

Let s start with 90 degrees bend which is the most simple scenario. There are a two major factors that affect how tight you can make the internal radius of a bend in a piece of sheet metal. Use this document to choose values that are both manufacturable and meet your needs. Being able to read a bend force chart is crucial for any brake press operator and sheet metal engineer.

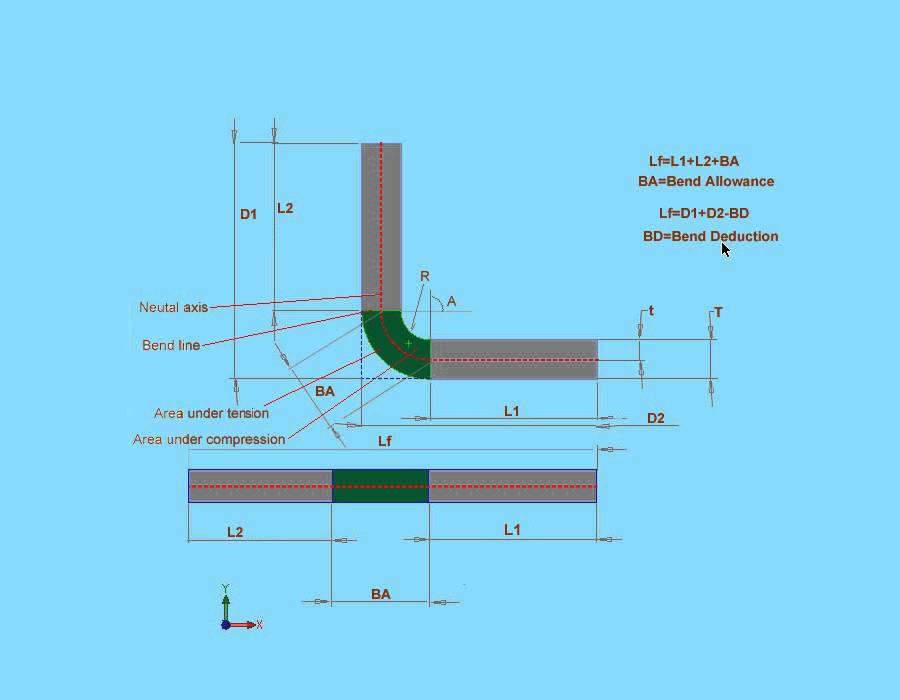

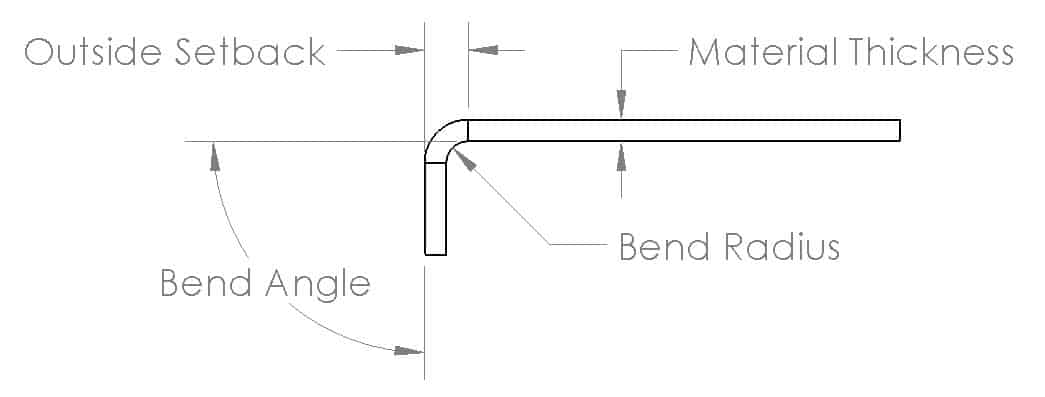

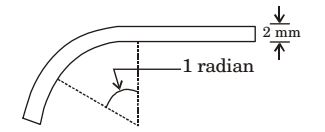

When the sheet metal is bent a bend radius is required at the bend. Let s say i have a 2 mm thick sheet and i want to bend it. We go beyond the general rules of sheet metal bending as our customers want tight bend radii for sheet metal parts. To keep it simple i also use a 2 mm inside radius.

If the bending radius is too small the bending will be cracked and if the bending radius is too large the bending is easy to rebound. Generally speaking the thicker a piece of sheet metal is the wider the internal bend radius will. An air bend force chart or force chart breaks down a number of key components of sheet metal bending in an easy to reference format. 60 90 and 120 and we will calculate k factor bend allowance and bend deduction for them.

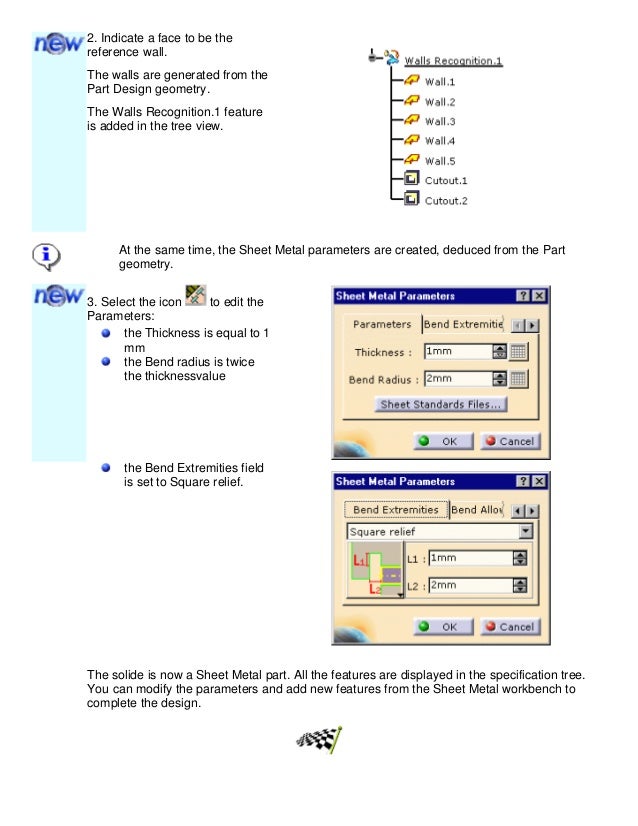

The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by protocase. I can now see that the minimum flange length is 8 5 mm for such a bend so i have to keep it in mind when designing. The thickness of the metal. The bending tool has a radius of 30 mm which means that our inside bend radius r is 30 mm.

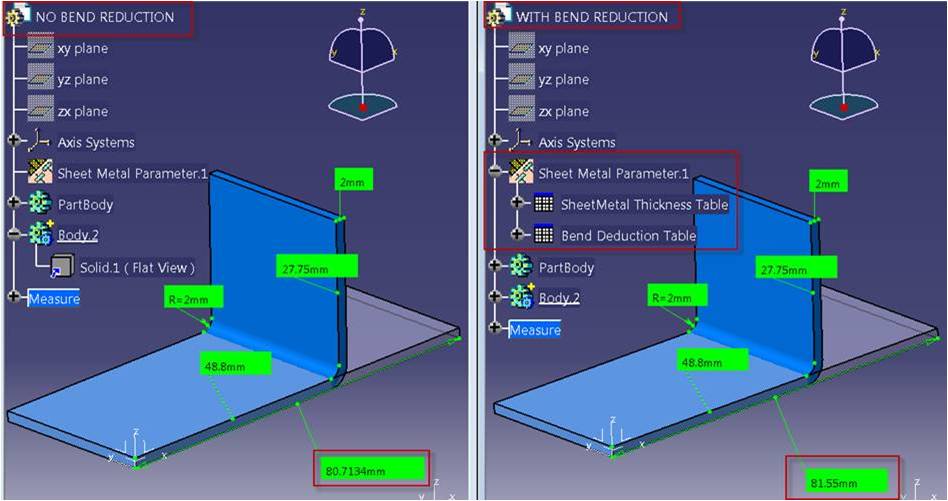

This tool allows you to determine tonnage internal radius v die opening and minimum flange you just have to insert the characteristics of the sheet metal to be bent. The gauge inside radius die opening and minimum flange length are all interconnected through different equations and relationships the air bend force. The hardness of the metal. Determining the minimum internal radius for a bend in sheet metal.

Bending radius there should have bending radius for sheet metal bending bending radius should not be too large or too small it should be chosen appropriately. It is most economical to use a single bend radius throughout the design but if necessary you can utilize multiple radii. The bending radius should not be too large or too small and should be chosen appropriately. The tool can calculate the required bending force for bending aluminum stainless steel mild steel and weldox or strenx high strength steels.

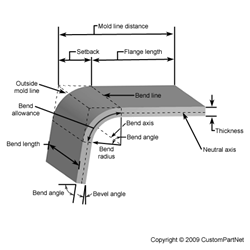

You will need to know your material thickness mt the bend angle b the inside radius ir and the k factor k. The bend allowance formula takes into account the geometries of bending and the properties of your metal to determine the bend allowance.