Bending 11 Gauge Sheet Metal

It was a little thinner from the factory but i have a sheet of 1 8 maybe 11 or 12ga already.

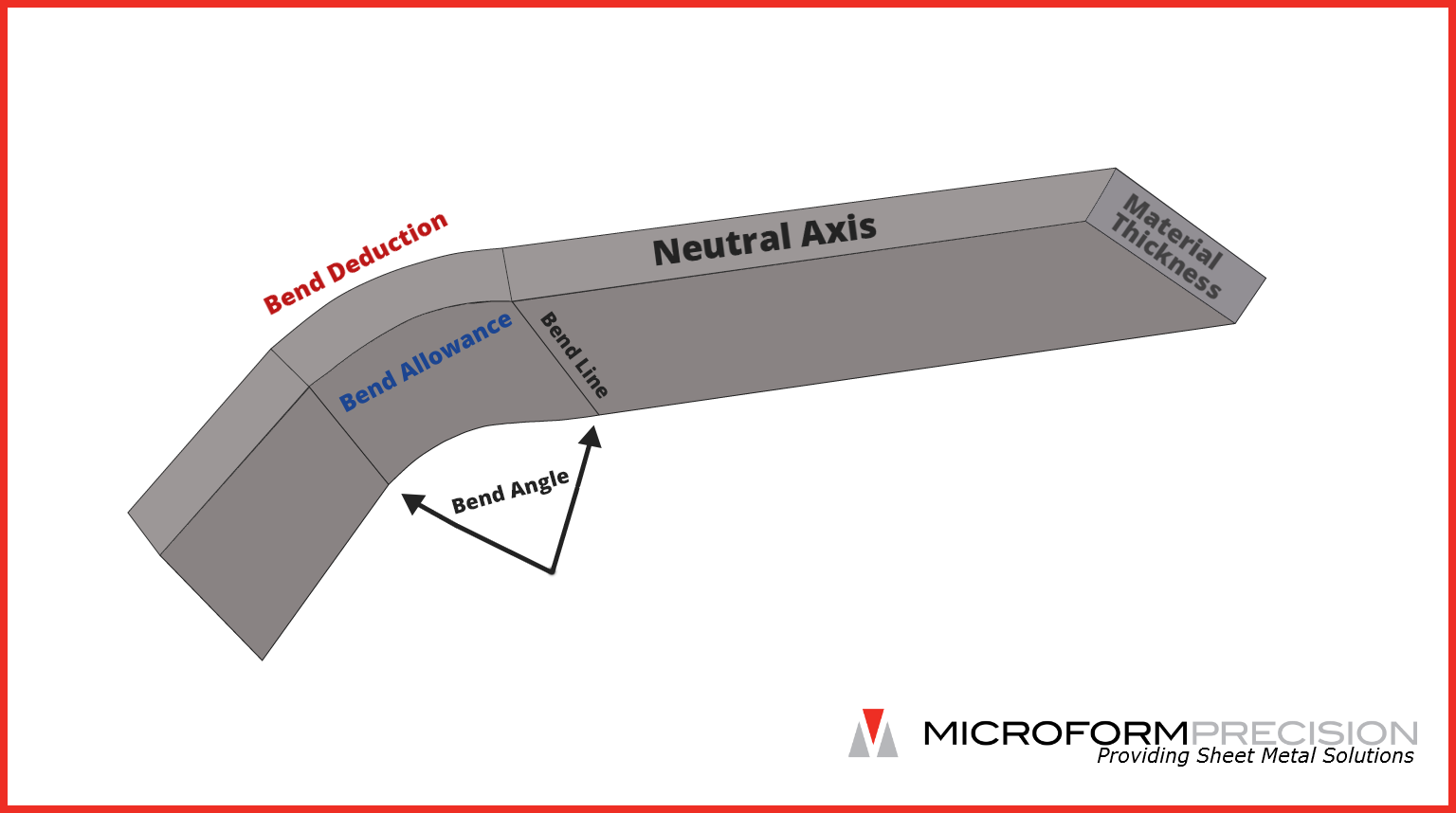

Bending 11 gauge sheet metal. A gauge conversion chart can be used to determine the actual thickness of sheet metal in inches or millimeters. The material thickness will be measured in decimal form not by the gauge number. Now that you know your bend allowance take your protractor and draw a clear line with your marker across the point at which you will bend your sheet metal. Total build cost was.

I need to bend up 2 sections that are about 14 long 4 tall and 3 5 wide. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. I m replacing a section of unibody frame. How to bend sheet metal without a brake.

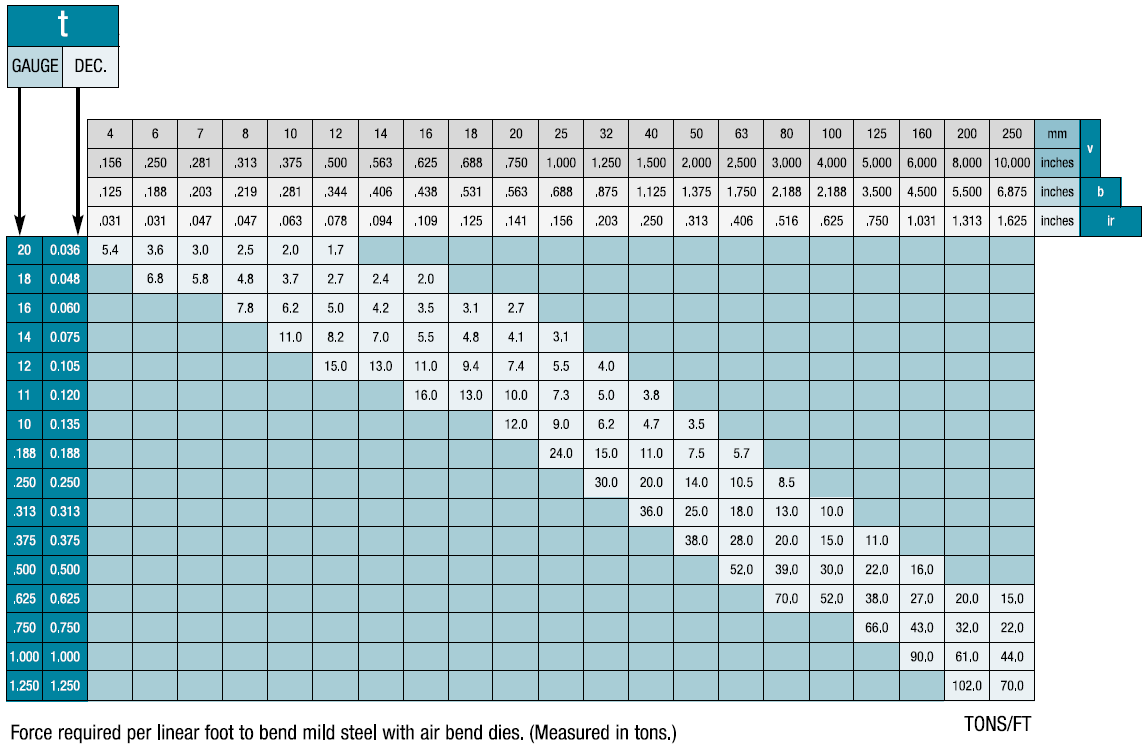

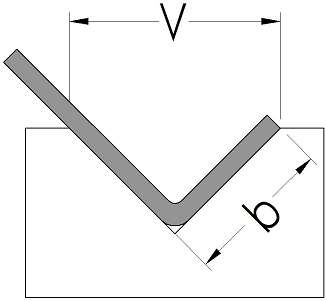

An air bend force chart or force chart breaks down a number of key components of sheet metal bending in an easy to reference format. How to bend sheet metal without a brake in 4 different methods with minimal or homemade tools. Metal shops have brakes mounted at different angles with automated braking arms however it is possible to bend sheet metal at home without the use of a brake. Being able to read a bend force chart is crucial for any brake press operator and sheet metal engineer.

The bend allowance formula takes into account the geometries of bending and the properties of your metal to determine the bend allowance. This is my version of a homemade bending brake for 10 gauge sheet metal. A little thicker is better in this case since the springs attach to it. Mark your bend lines.

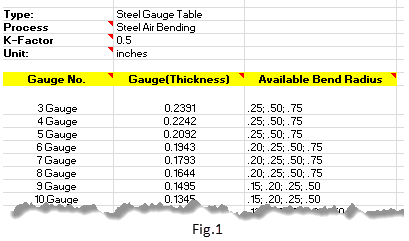

Then use your bend allowance to draw your second bend line the intervening distance between your bend lines bend radius. Material bend radii and minimum bend size charts. The gauge inside radius die opening and minimum flange length are all interconnected through different equations and relationships the air bend force. You will need to know your material thickness mt the bend angle b the inside radius ir and the k factor k.

Shop 13 manual bending brakes at northern tool equipment. For example 18 gauge steel according to a gauge conversion chart is 0 0478 inch or 1 214 millimeter. When working with sheet metal one particularly useful piece of equipment is the brake.