Bending 6061 Aluminum Sheet

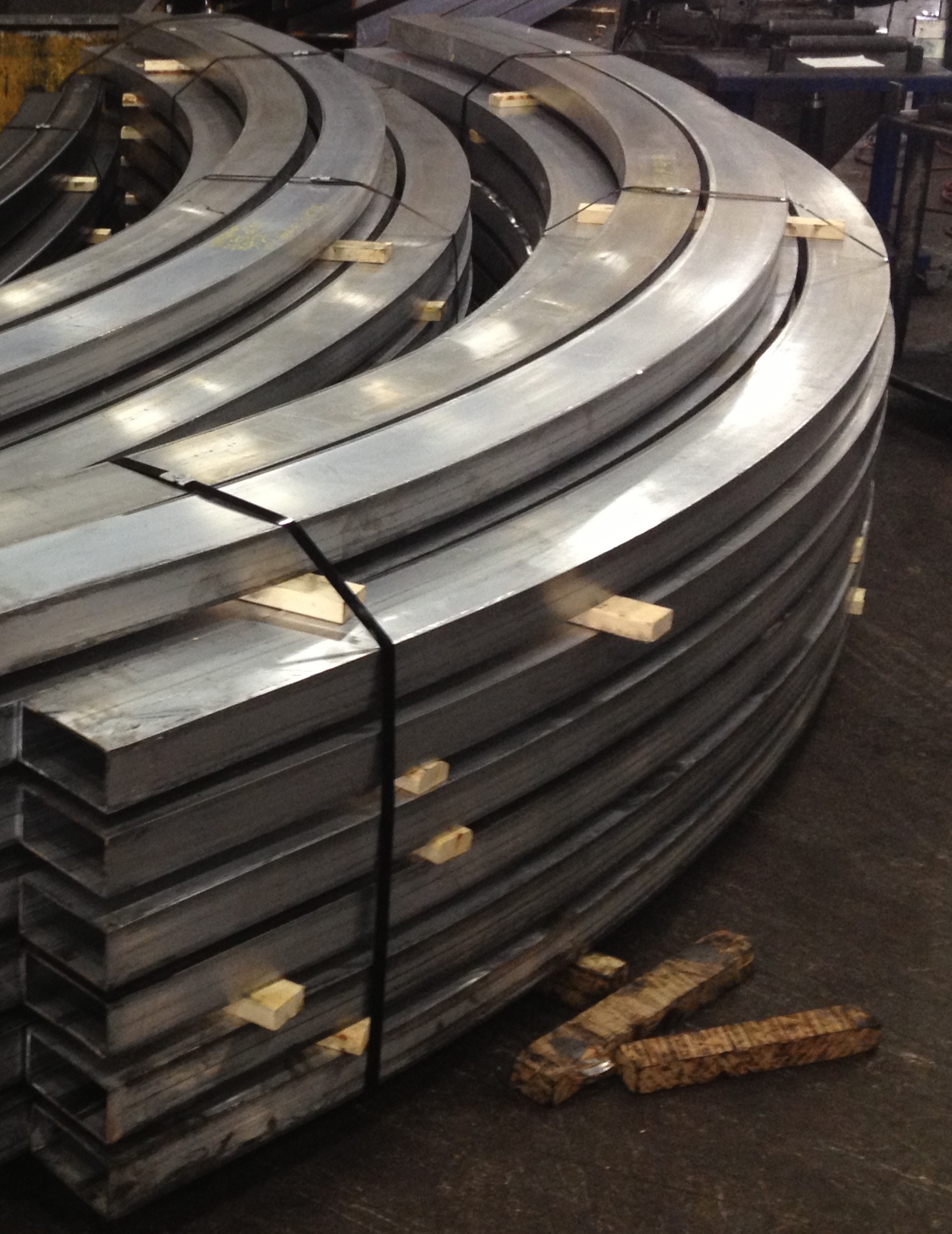

From a bending perspective it s always best to bend these parts in an annealed state and then temper them to the correct condition.

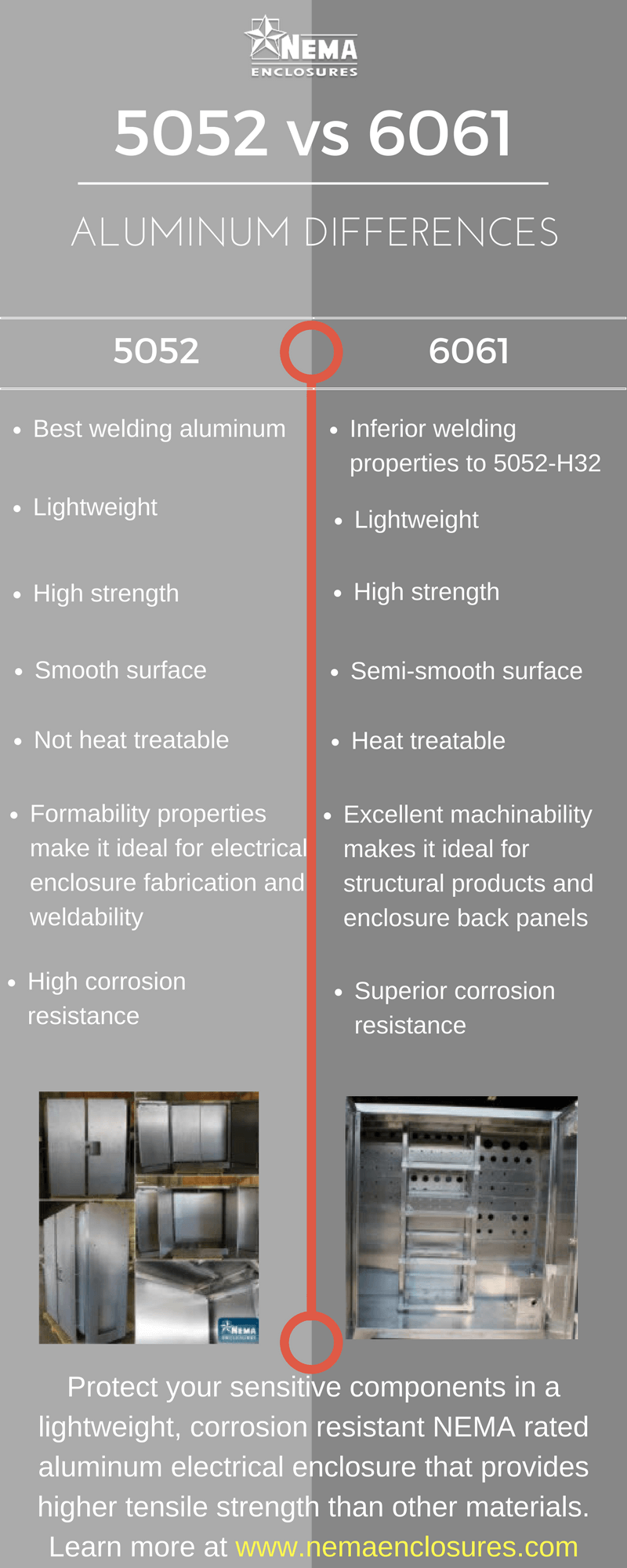

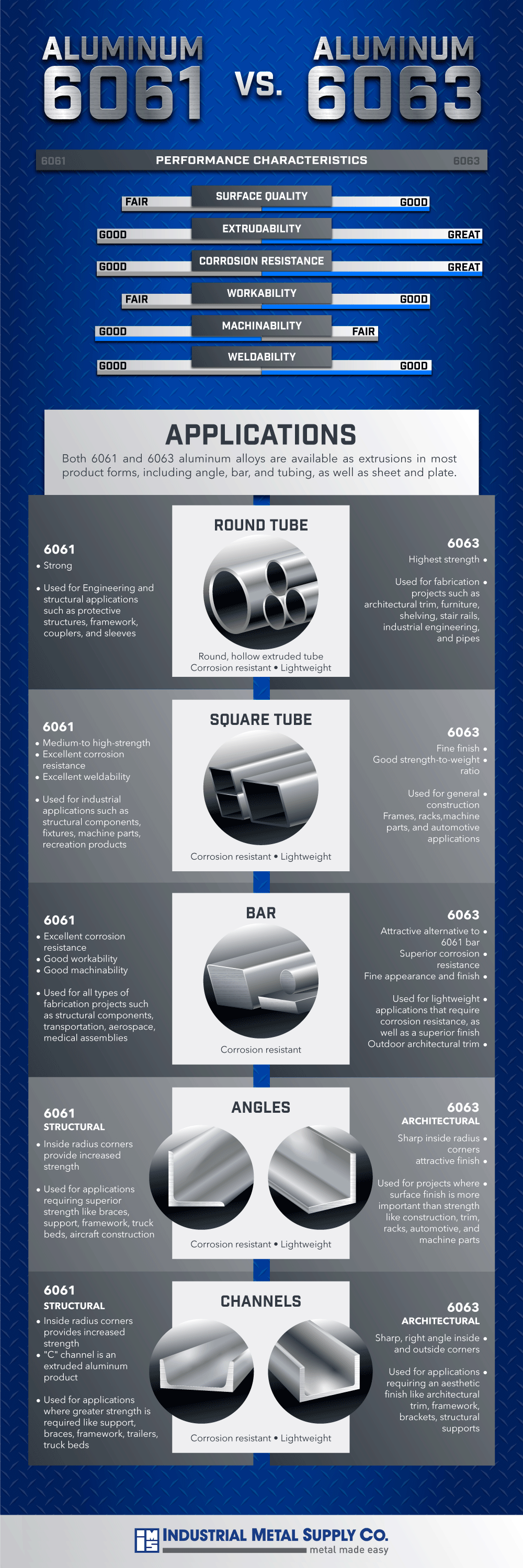

Bending 6061 aluminum sheet. Aluminum where necessary 5052 h32 may be bent to 1t and 6061 t6 to 1 1 2t. 6061 temper designations and definitions alcoa produces 6061 alloy with a wide selection of standard and special tempers. 1 4 in. O 0 0 0 1t 1t 1t 1 1 2 t 2t.

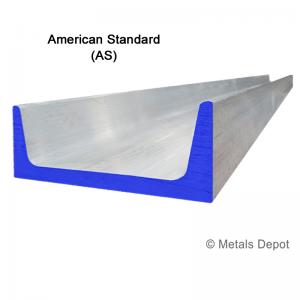

When moving up to t4 and t6 tempers however bending ability tends to decrease. 1 2 in. 3 16 in. Steel american iron and steel institute 1 see aisi s fabrication guidlines for cold bending thk 6061 t6.

The general purpose 6061 aluminum sheet plate is heat treatable resists cracking due to stress and is easy to weld and machine but limited on formability. Here the alloy is 6061 and the temper is t6 meaning the alloy has been thermally treated. The 6061t6 aluminum sheet is easy to wrinkle or crack on the side of the bent surface. The 6061t6 aluminum sheet can be bent but the hardness of the t6 temper is high.

In the annealed condition o temper 6061 is extremely ductile and well suited for severe forming applications. 1 8 in. In the annealed condition it can be used for bending since the difference between yield and tensile strength is 10 ksi and elongation is up to 18. Recommended minimum bend radii for 90 degree cold forming of sheet plate temper 1 64 in.

That s the ideal anyway but the reality is that many parts arrive at the press brake in a less than ideal state. 6061 aluminum sheet plate offers a combination of higher strength good corrosion resistance and machinability making the 6061 grade the most widely used aluminum sheet and plate grade available for all types of fabrication projects. Material suppliers have tables that show the approximate minimum inside bend radius for the various alloys the temper condition of each and the minimum allowable inside radius at 90 degrees of bend angle. 3 8 in.

This is one of the most versatile of the heat treatable family of alloys. 1 16 in. The aluminum plate has a high hardness and a90 degree bending is easy to crack but there are certain differences in the bending of different aluminum alloys. When solution heat treated and naturally aged t4 condition 6061 has good formability for bending.