Bending Acrylic Sheet Max Bend

If the material is at 160 degrees celsius it can be bent.

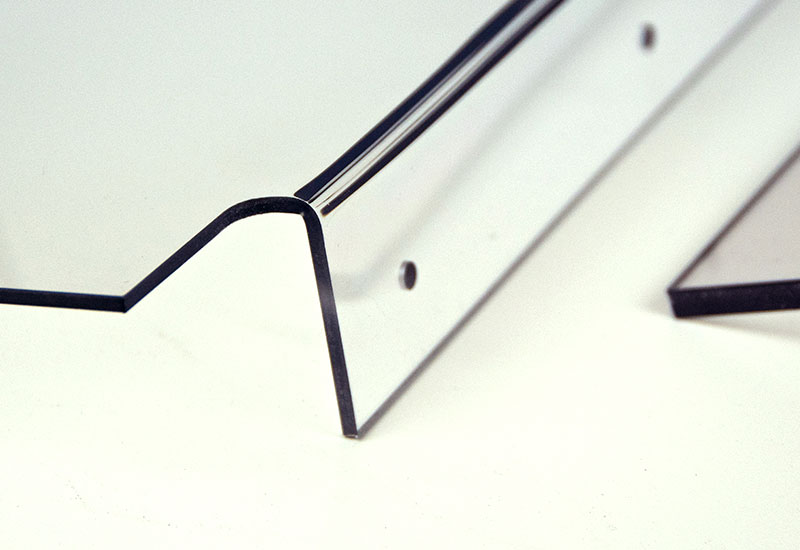

Bending acrylic sheet max bend. Plus you can permanently bend these plastic sheets for multiple projects like making display cases or artwork with a bending fixture a few tools and the right steps. Today we re using a line bender to form some acrylic for our new cnc dust shroud. Extruded sheet should be heated to between 290 and 320 f 145 and 160 c. Figure 2 illustrates the sheet that is bent with the bend angle of 90 degrees.

The freight for 1 2 x 48 x 96 sheet of gray acrylic is 90 00 sometimes there is a 65 00 pallet charge. Line bending or thermoforming a brasion resistant acrylic sheet is not recommended. Acrylic sheets are perfect for home decor because they re affordable sturdy and come in a variety of thicknesses and colors. Make your pressure on the acrylic as even as possible while you push.

Please keep in mind the bigger and thicker the part is the more it cost to bend. The acrylic sheet is laid over a long thin filament with the bending line just above the wire. There are three main types of plexiglas cell cast acrylic sheet continuous cast acrylic sheets leave a reply cancel comment reply you must be logged in to post a comment. Professionals who bend acrylate regularly or bend acrylic sheet do so with the aid of a filament.

The freight on a 1 2 x 48 x 96 sheet of clear acrylic is 0 0. First sketch out your. Step 1 designing. If you d like to reach out to us to.

From there we can calculate the k factor and the bend deduction. To set up your plastic or acrylic sheet to bend simple curves for your miniature and model projects you need to first remove the protective covering from the material you wish to bend. After bending the sheet we need to do some measurements as shown in figure 2. Prepare your heat gun for bending the acrylic.

Cold forming is possible. Use long thin 1 inch or so in width test strips to practice your technique and learn how your. Use the spare piece of flat scrap wood to push the acrylic back and down while you aim the heat gun at the acrylic. Heating is a slow process in order to make sure that you get a straight bend in the acrylic.

90 degrees bend angle. We will start by calculating the bend allowance. It becomes soft and can then be properly although care must be taken. Once you go past a 48 x 96 sheet costs can skyrocket.