Bending Aluminum Sheet 3 16

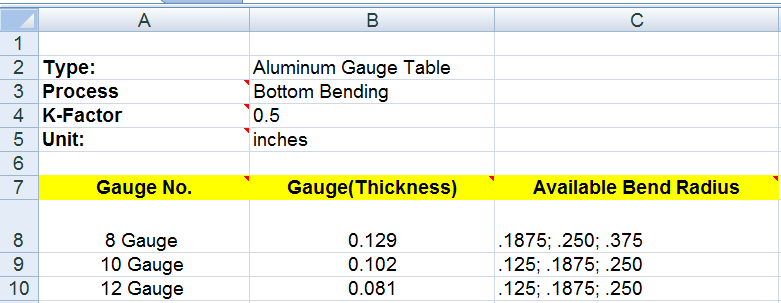

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend.

Bending aluminum sheet 3 16. Make sure the bar is seated firmly inside the frame. Say you re bending 0 25 in thick 6061 t6 aluminum to a 100 degree external angle 80 degree internal angle. Then place the clamp bar back down on top of the aluminum crosswise. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle.

This weakens the aluminium and creates a fracture line. Place the fracture line over the edge of a table and bend the overhang slightly downwards. Lift the clamp bar away from the rear of the brake frame and slide the sheet in perpendicularly to the direction you want to bend it. When moving up to t4 and t6 tempers however bending ability tends to decrease.

How to bend sheet metal without a brake. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. This is one of the most versatile of the heat treatable family of alloys. Flip the sheet over and repeat.

You d probably air bend by using a 3 0 in. Die opening with a relieved profile. How to bend sheet metal without a brake in 4 different methods with minimal or homemade tools. To make this easier you d start with your 6061 material in the soft t 0 state.

Most frequently expensive sheet metal bending tools called brakes are used to bend sheet metal but you can also complete this task without one. Learn how to bend sheet metal so you. Insert your aluminum sheet into the brake beneath the removable clamp bar. I had to bend some aluminum ears on mounting plate for my underwater camera and lights this is how i did it the wrong way a costly mistake and then how i d.

Material bend radii and minimum bend size charts please note.

.JPG)