Bending Aluminum Sheet 90

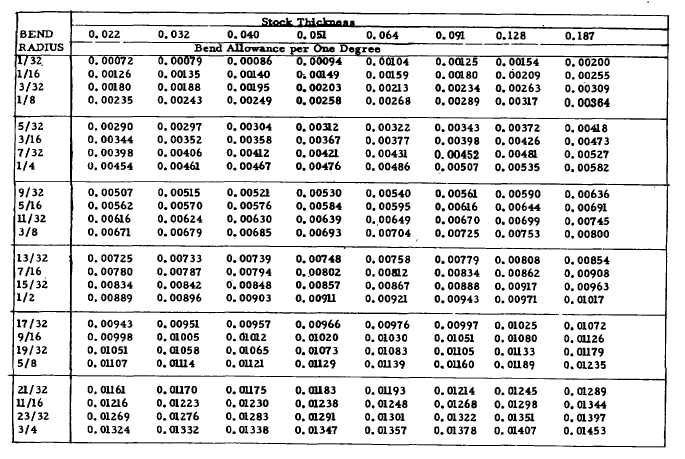

As an example if you want to bend 24 gauge sheet metal at a 90 angle the calculation would be.

Bending aluminum sheet 90. In high purity forms aluminum is soft and ductile. Make sure the bar is seated firmly inside the frame. The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius. The two m10 bolts in the top are to clamp the sheet between the backstop and the base.

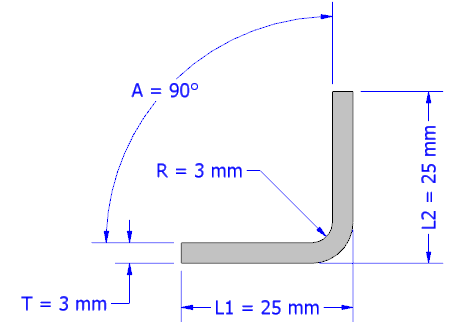

The aluminum series ability to bend tends to decrease as you move down the list of tempers from annealed to t4 and t6. Which aluminum alloy bends the best is a a common question customers want the answer to. Insert your aluminum sheet into the brake beneath the removable clamp bar. To think about bending a sheet of metal that has appreciable thickness focus on an imaginary central sheet the so called neutral line or neutral axis within the thickness.

Bending a brittle metal beyond its limits could cause the metal to snap and break. Bending is a delicate and demanding process most of the time and common fabricating processes require a degree of formability that make your choice of proper alloy critical. Bend allowance mild sheet steel 90 degree bend allowance. There is also the thickness of the aluminum sheet.

Material bend radii and minimum bend size charts please note. Ossb for α 90. 032 18 ga 040 16 ga. In this post we ll explain it to you.

Lift the clamp bar away from the rear of the brake frame and slide the sheet in perpendicularly to the direction you want to bend it. Then place the clamp bar back down on top of the aluminum crosswise. When you release the handle the bent material will spring back to 90 not 85. The idea of adding an angle 5 degrees past 90 is so that you can bend past 90 to allow for the spring back.

Use the minimum bend dimension values in the charts below for your minimum closeness of cutout to a bend. When bending the aluminum sheet to 90 degrees usually 1000 series 3000 series 5000 series aluminum sheet is common used 6061t6 aluminum sheet and 7000 series aluminum sheet has too high hardness it is necessary to do the annealing treatment to the o state before bending.