Bending Galvanized Sheet Metal Over Gable

A cutout or the edge of your flange to your bend.

Bending galvanized sheet metal over gable. This is done through the application of force on a workpiece. Astm a 143 recommends the minimum bend radius for any part that will be hot dip galvanized after bending be at least three times the material s thickness. Next put your wooden or metal form blocks in the vice and clamp your sheet of metal between the forms. Determine your minimum bend by measuring the distance from your closest feature i e.

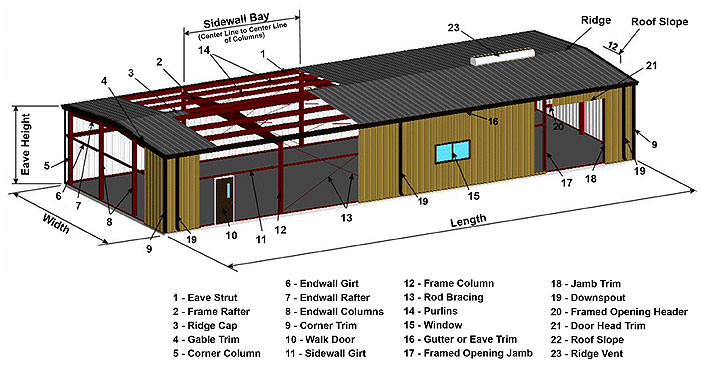

Choose a bend radius that matches your minimum bend. Simple sheet metal bender using a hand roller clamps and plywood. It is not suited for flat or low slope. If your sheet metal is long ask a friend to stabilize the part hanging out from the form blocks so it doesn t affect the bend.

This allows for some cold work in the bend area without causing cracking of the steel. Move slowly to avoid breaking the metal. Bending after hot dip galvanizing is sometimes necessary if the parts do not fit into their intended spot. Unclamp the metal and gently bend it in the correct direction.

The force must exceed the material s yield strength to achieve a plastic deformation. To bend sheet metal in a vice start by marking a line on the metal where you want to bend it. Frame the basic gable roof with trusses to any suitable pitch. If you have any questions or want to discuss your design contact us.

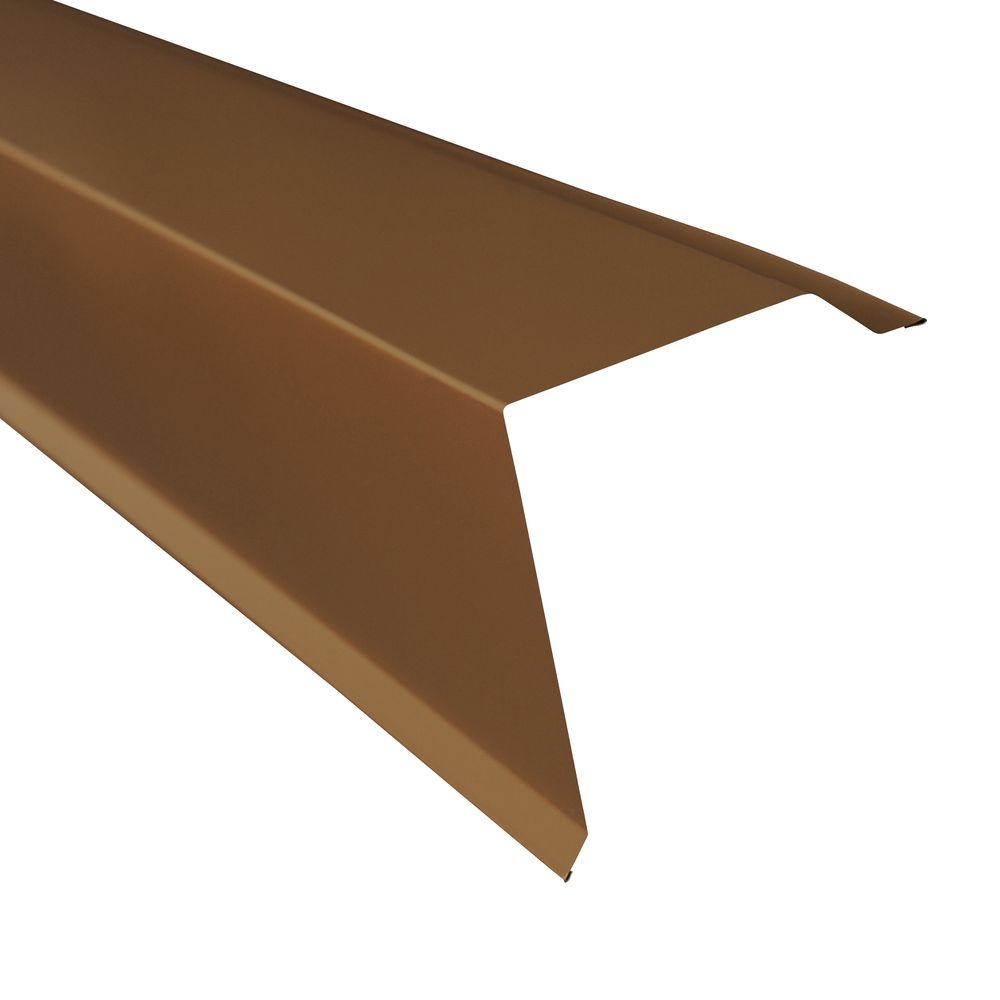

Monkeys spinning monkeys by kevin macleod. Stop bending once you reach the correct angle and release it. Gibraltar s galvanized steel gable rake flashing is applied over metal panels along the rake edge to direct rain water away from the fascia. Install metal roofing only with a pitch of 4 12 which rises 4 inches per foot or steeper.

Abn sheet metal hand seamer 3 inch straight jaw manual metal bender tool sheet metal bending pliers flattening tool 4 5 out of 5 stars 137 27 89 27. Bending is one of the most common sheet metal fabrication operations.