Blackened Steel Sheet Thickness

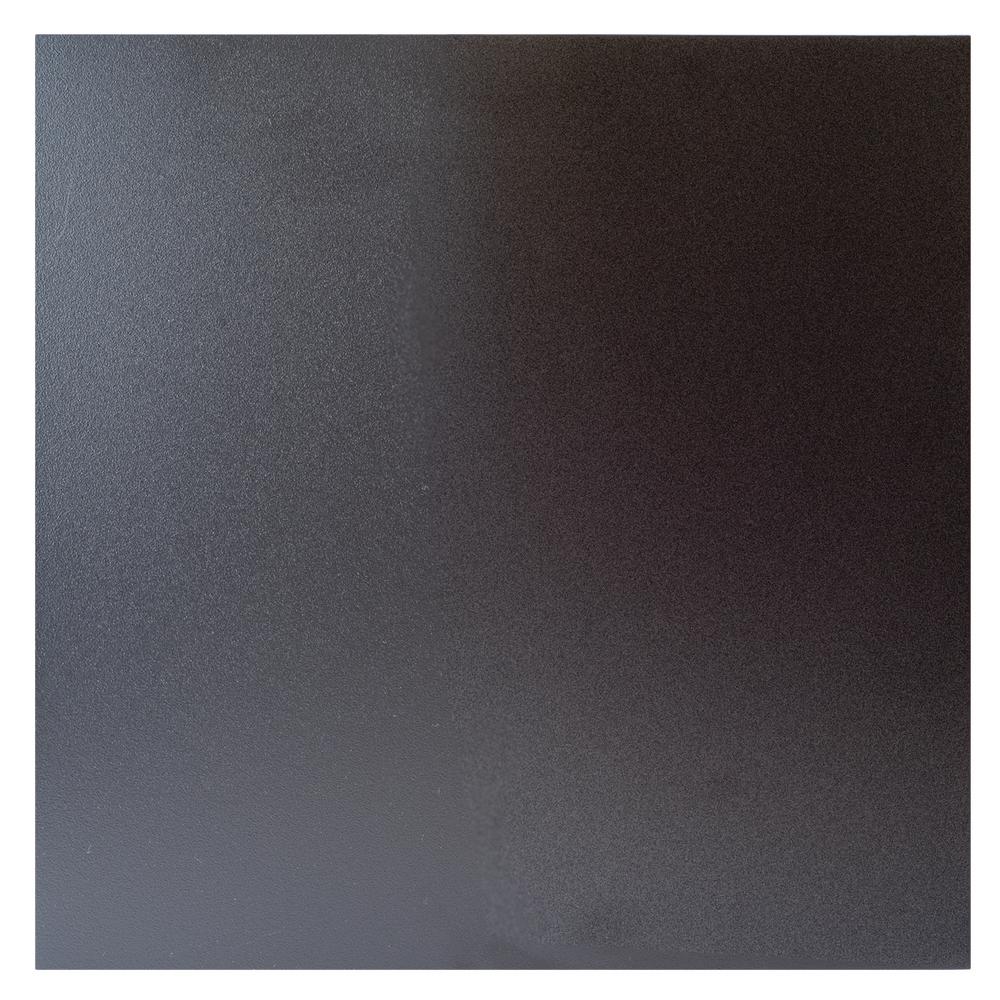

Mg mcgrath custom finishing s pre blackened steel finishes provide architects and designers with a raw look of darkened a606 alloy steel on a mill surface.

Blackened steel sheet thickness. Our team of craftsmen produce this finish through a proprietary process of cleaning and develop the final finish with a mixture of color tints and multiple clear. A gauge conversion chart can be used to determine the actual thickness of sheet metal in inches or millimeters. Unit 4 yakira buildings 83 sefton lane maghull liverpool l31 8bu. 44 151 526 4777 fax.

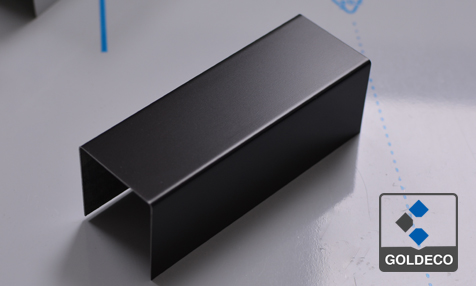

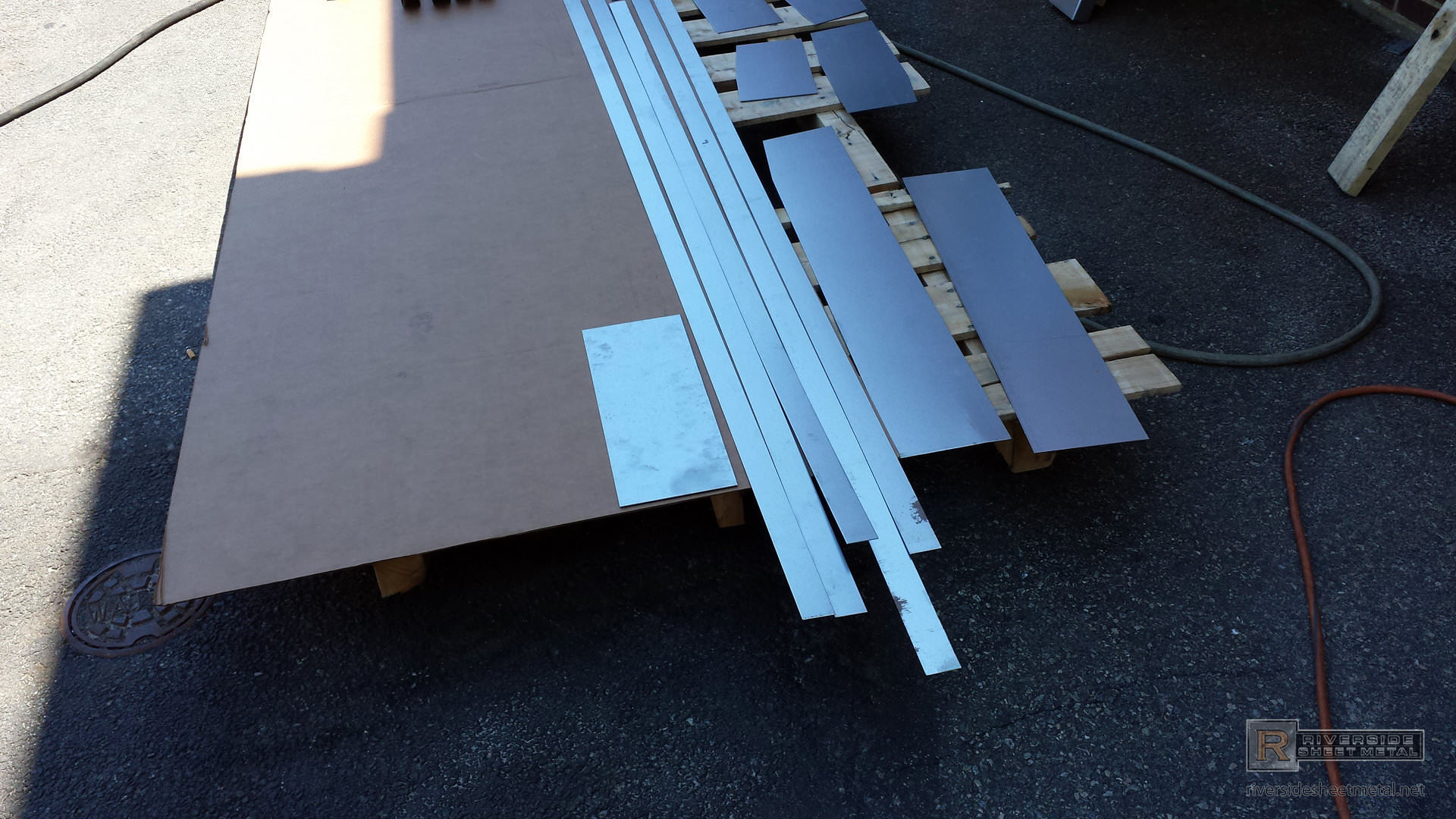

The pvd physical vapor deposition surface treatment is quote durable and is actually harder than the stainless steel surface itself. Blackened steel panels this project consisted of cold rolled steel panels with a blackened patina finish. The black stainless steel is available in 304 and 316 stainless steel and offers an attractive finish for general 304 and harsh environments 316. The equivalent thicknesses differ for each gauge size standard which were developed based on the weight of the sheet for a given material.

For example 18 gauge steel according to a gauge conversion chart is 0 0478 inch or 1 214 millimeter. 44 560 115 7793 email. Among the processes include chemical baths and finishes cold coatings hot coatings with various levels of success. Blackened steel refers to a number of techniques which can be used to produce a blackened finish on steels.

In many architectural uses blackened steel may refer to galvanized steel with a blackened zinc patina oxide. Galvanized zinc coated steel sheets are most often required for exterior applications of this decorative finish. Gauge or gage sizes are numbers that indicate the thickness of a piece of sheet metal with a higher number referring to a thinner sheet. This sounds great but don t misunderstand.

To protect the panels from the harsh environment surrounding the elevator a clear poly base coat was applied w a satin wax finish.