Blanking Die Clear Sheet Metal

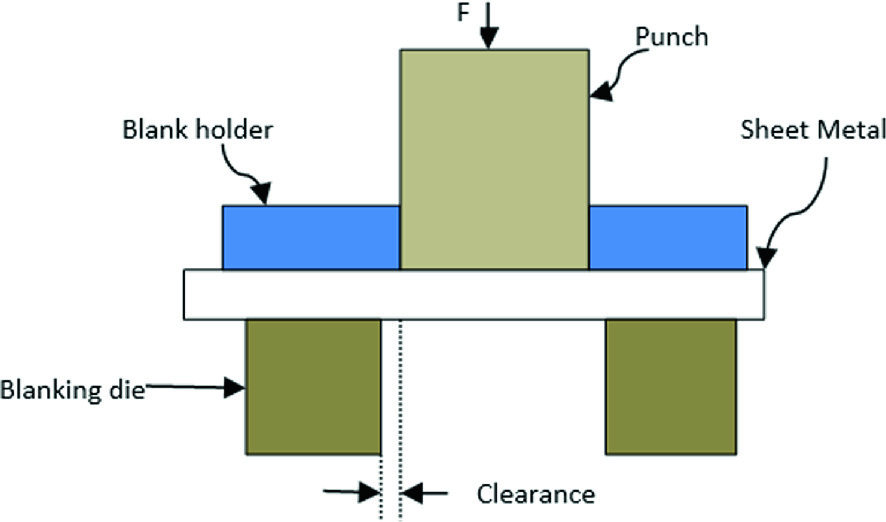

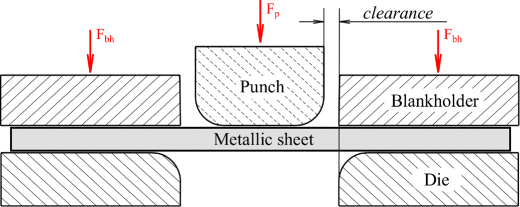

The sheet metal is placed on the blanking press of die.

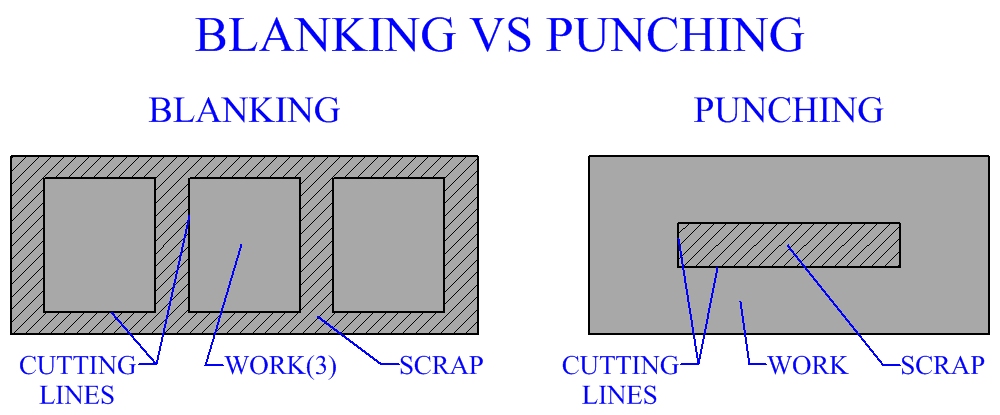

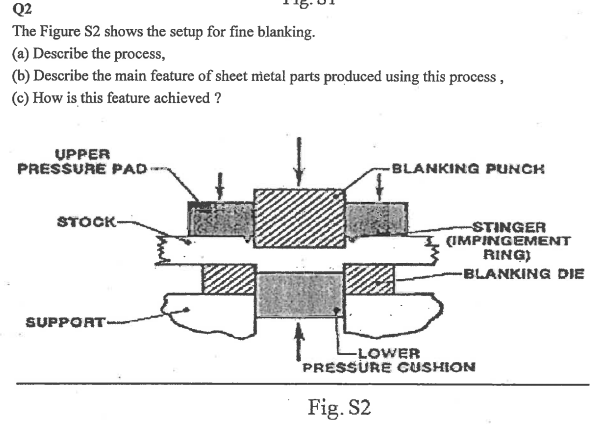

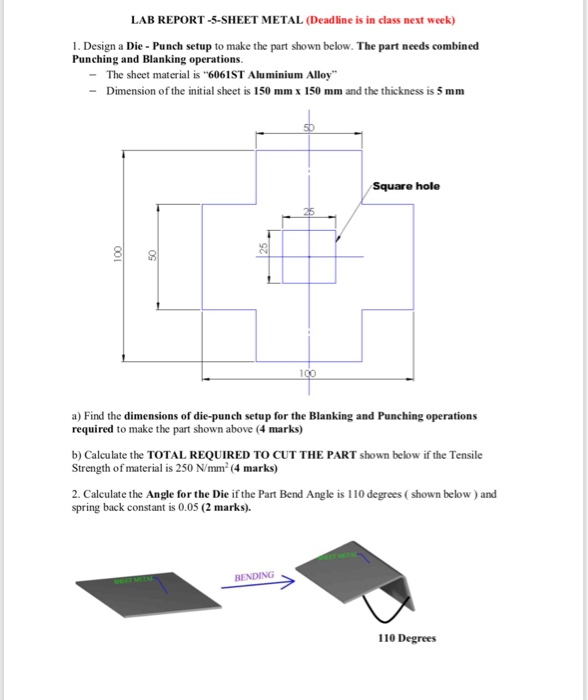

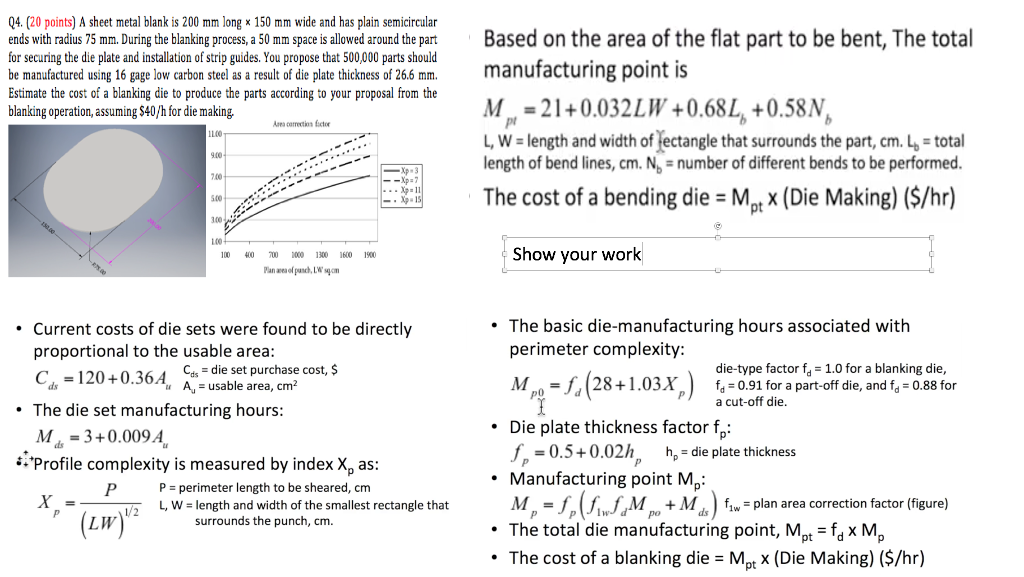

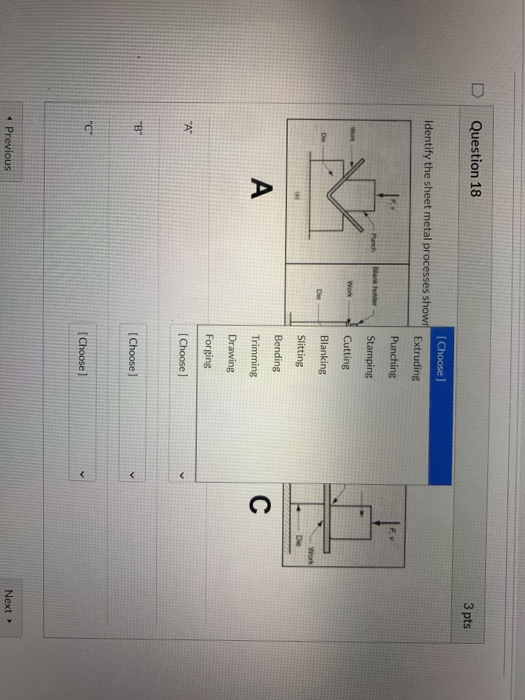

Blanking die clear sheet metal. Unipunch tooling is used in applications where the punch slug is the blank. Fineblanking can be used on a variety of metals including tool steel. Blanking blanking is a metal fabricating process during which a metal workpiece is removed from the primary metal strip or sheet when it is punched. In this article i will be exploring the 5 types of dies used in sheet metal operations at respective stages and strokes.

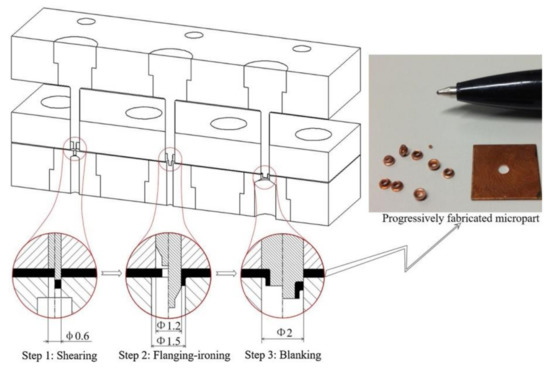

For the forming of sheet metal such as automobile body parts two parts may be used. Blanked parts can be shaved to an accuracy of up to 0 025 mm 0 001 in. Parts can be run progressively and coining and embossing can be incorporated into the process. Either both punch and die are made with carbide or tool steel.

The material that is removed is the new metal workpiece or blank. Sign of the end of the blanking. The die cavity instead of have a cutout shape of desired shape and made of standard shape is formed together. A shearing die can also be called a punch or blanking die.

A straight smooth edge is provided and therefore shaving is frequently performed on instrument parts watch and clock parts and the like. Characteristics of the blanking process include. It also is suitable for use on heavy metals up to 0 625 in. Blanking metal blanking is the process of cutting a desired shape out of a flat piece of sheet metal.

Products made with dies range from simple paper clips to complex pieces used in advanced technology. Unipunch custom metal fabrication c frame punching units will increase throughput reduce changeover time and enhance overall quality. Blanking is a stamping process in which a mold is used to separate a portion of a sheet from another portion along a certain contour shape simply speaking blanking is the process of using a mold to separate the sheets. The workpiece may pass through several stages using different tools or operations to obtain the final form.

Thick even for making small holes. The process is relatively fast. Like molds dies are generally customized to the item they are used to create. A die either a punch or a matrix used for making a design or pattern which stands out in low relief from the surface of a sheet of metal is an embossing die.

Different types of dies. The punch passes through the sheet into the die. A special die that cuts or punches out a shape from a sheet of metal is a shearing die. Let s make holes faster.