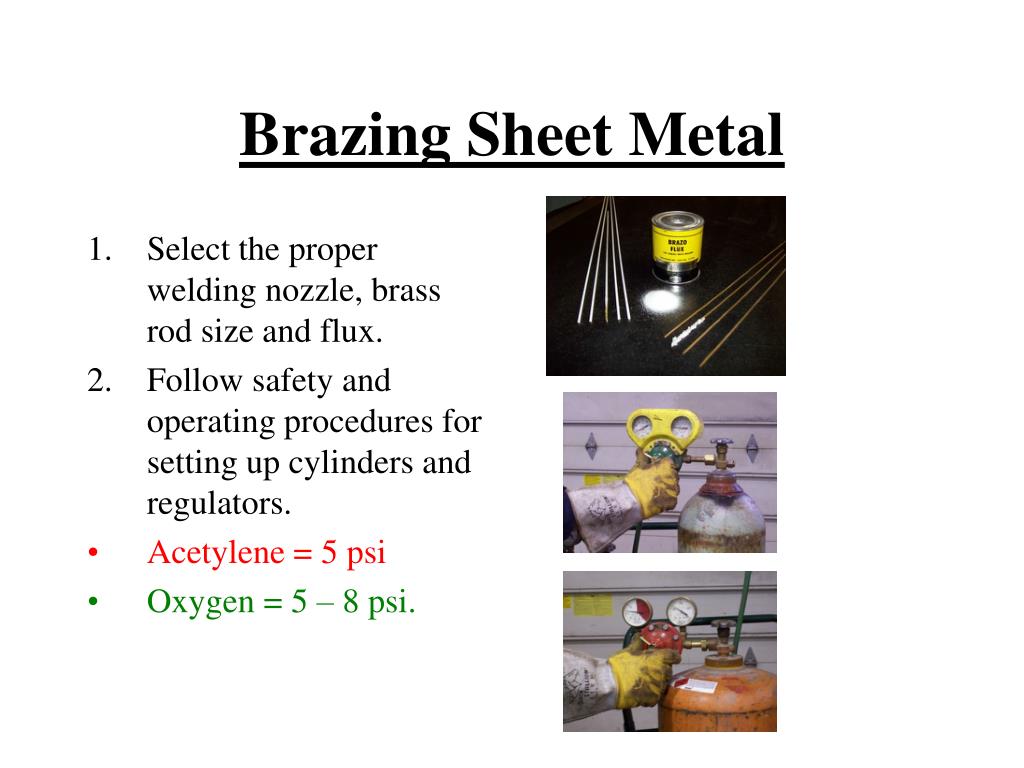

Brazing Sheet Metal Oxy Acetylene

Jeff shows how to braze using an oxygen and acetylene how to set your gas mixture and the correct way to light your torch.

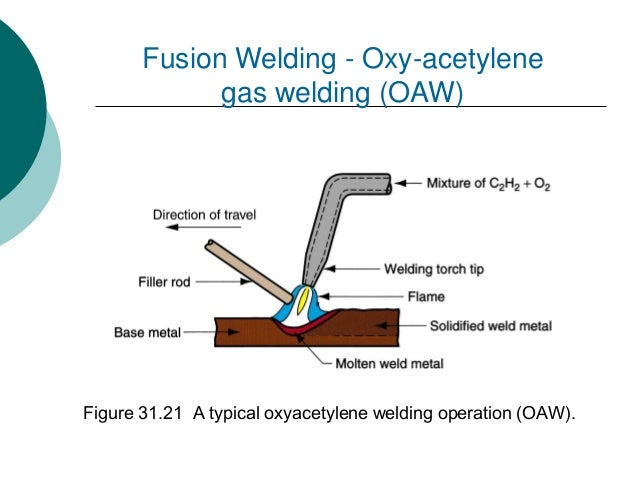

Brazing sheet metal oxy acetylene. For large areas heat portions of the joint to temperature and then move to the next adjacent area. Read our general safety precautions before starting your project. Oxy fuel or oxy acetylene welding are gas welding procedures that were invented in the early 1900 s. Oxy acetylene gas welding brazing and braze welding these are older methods of joining thin metal sections that still have some application in today s world of mostly electric welding.

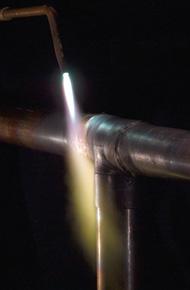

In addition to the purposes of welding connecting gas welding can also be used as preheating brazing cutting and hard facing. Heat the joint where the two pieces of metal will meet until the joint glows. Oxy acetylene welding oxy acetylene welding and sheet metal. While alternate fuel gases are available most contractors still use acetylene.

Apply the brazing rod to the joint while continuing to heat the metal surfaces. With the acetylene valve on the torch slightly open adjust the regulator pressure to the correct reading then close the torch valve. And this welding process is still very popular today mainly because it does not require much equipment and does not require power. Welding process oxyacetylene welding and brazing is practiced by several metalworking suppliers across the globe.

For brazing there are generally two equipment options to choose from. When brazing and soldering most hvacr technicians routinely use manual torches as their heat source. At the end of the. In most cases they will prove inferior in one or more of several ways to electric welding approaches.

Oxy acetylene welding is a welding process manually in which the surfaces to be joined which is warming to melt by a gas flame oxyacetylene with or without filler metal where the connection process without emphasis. Start by open the valve on top of the oxygen cylinder all the way and the valve on top of the acetylene cylinder 1 turns. After brazing use a wire brush to clean the brazed surface to remove any oxidation or residue.