Breaking Down Plywood Sheets

If you don t have a truck check with the place you bought the plywood and see if they can cut it.

Breaking down plywood sheets. The trickiest part about maneuvering sheet goods is getting it positioned vertically and. If you re buying new 2x4 studs are the way to go. Making the cutting frames. And the rip cut is way cheaper than a table saw 34 versus 300 no contest.

I keep two circular saws handy in my shop i know that isn t feasible for everyone but. Setting up plywood cutting station. Plus you can swap the edge guide to either side of the rip cut which means if you re lefty you can use too. Lifting plywood by yourself.

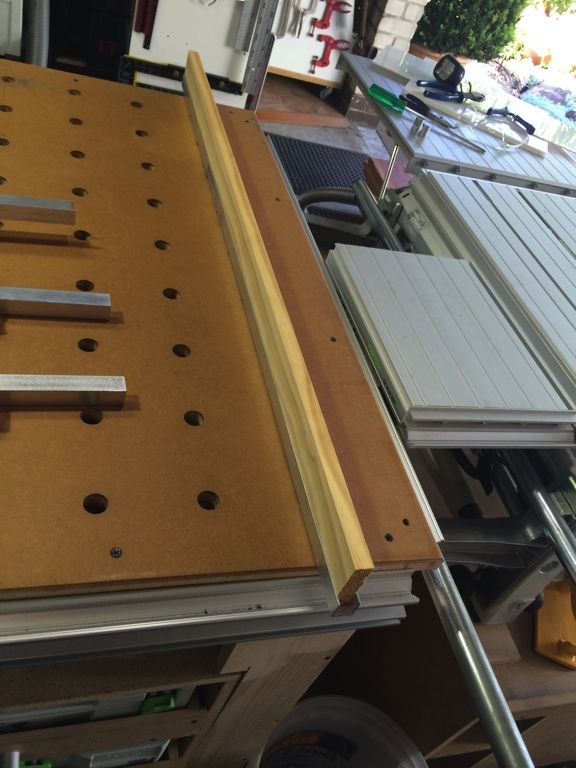

No more trying to shove full sheets of plywood through a small job site tablesaw. In fact some 3 4 t. How to move maneuver and break down plywood transporting plywood. But for those first few years i was really only using the track saw to break down sheets of plywood into their rough parts which i would then run through the tablesaw for final sizing.

When i got my first track saw years ago it was an absolute game changer for my trim carpentry work. Saw guide at least 96 inches long home depot lowe s sell a 2 piece saw guide with clamps for about. Handling 4x8 sheets of plywood medium density fiberboard mdf or other sheet goods by yourself can be tricky cumbersome and unsafe. Cutting plywood with a circular saw a great way to initially cut your plywood sheets down to more manageable sizes is to use your circular saw.

Setting up circular saw. How to break down a full sheet of plywood step 1. What i usually do is set up saw horses or in some cases my infeed table and my outfeed roller stands to support the plywood. In fact you can cut a 4 x 8 foot sheet of plywood in half without making any marks on it.

Use your saw horses or any work bench to support the bulk of the plywood.