Burr Direction In Sheet Metal

Burrs can interfere with subsequent forming processes.

Burr direction in sheet metal. And using a lower speed around 6000 7500 rpms makes all the difference in the world dressing and de burring edges on sheet metal and lite guage stock. To minimize instances and severity of burrs avoid sharp corners and complex cutouts when possible. It left some metal behind which solidified into burrs at the bottom of the cut. Burrs are most commonly created by machining operations such as grinding drilling milling engraving or turning.

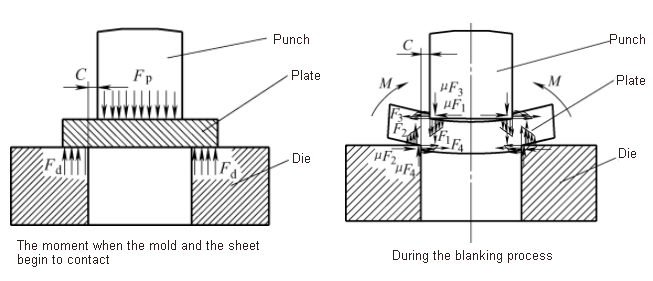

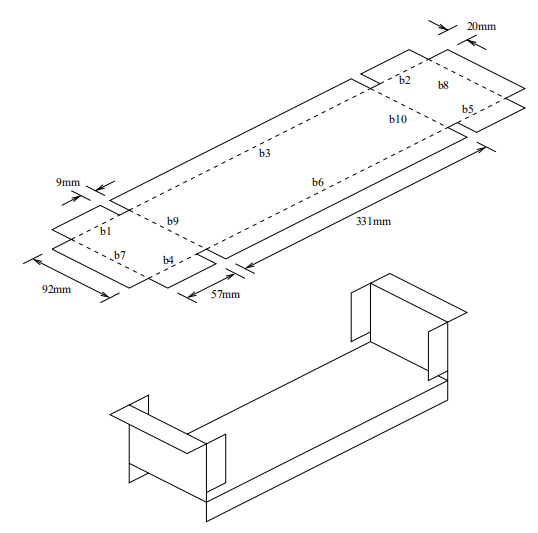

This type of burr is commonly. Some metals deform more than others and so form larger burrs. When such factors cannot be avoided be sure to note burr direction in your design so they can be taken into account during stamping see the stamped edges image below. This disturbed the gas flow dynamics which in turn did not evacuate the right amount of molten metal at the right time.

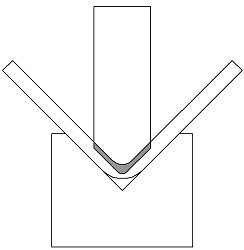

It just makes another bur going the same direction as the wheel. Consider a punching operation as an example. Adjust so that the cutting is uniform. Engineers designing sheet metal enclosures and assemblies often end up redesigning them so they can be manufactured.

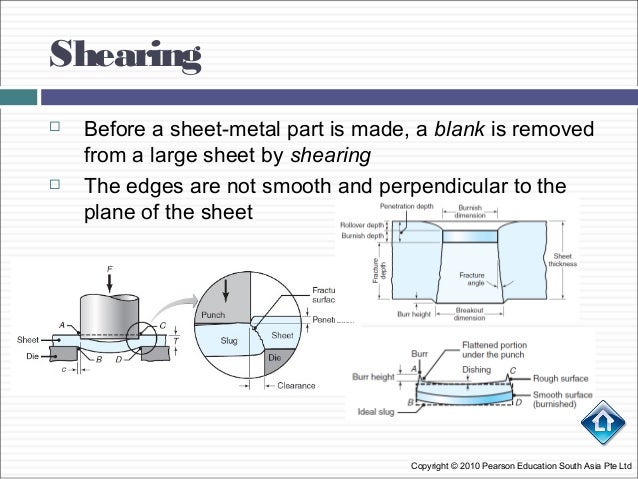

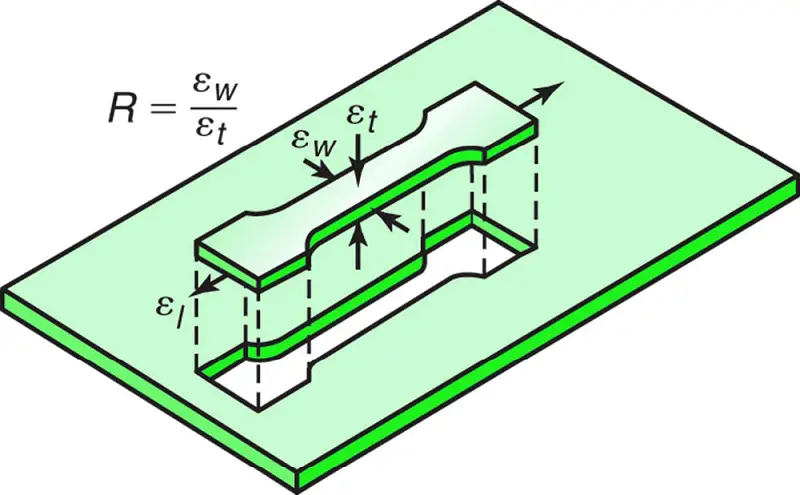

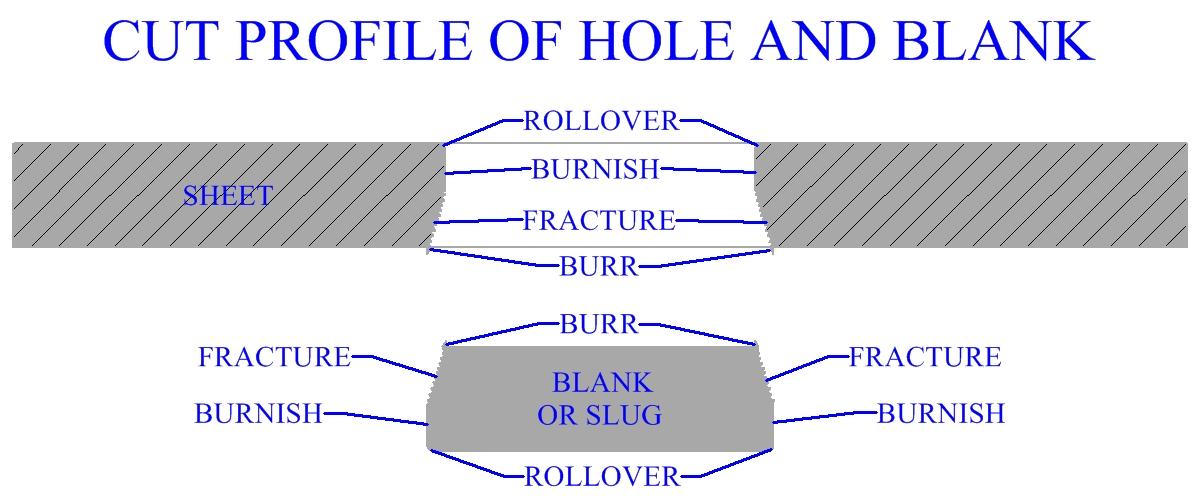

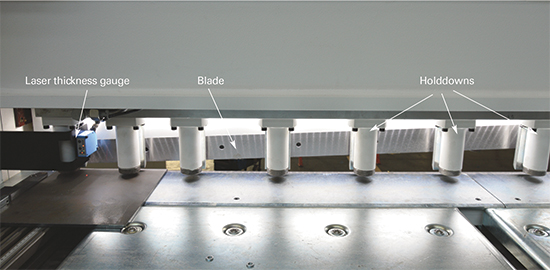

Burr direction side of the stock on which burrs appear. Burr height height to which burr is raised beyond the surface of the material. All surface zones of cut sheet metal occur in the opposite order on the sheet than on the blank or slug. De burr machine is the best for sheet very quick.

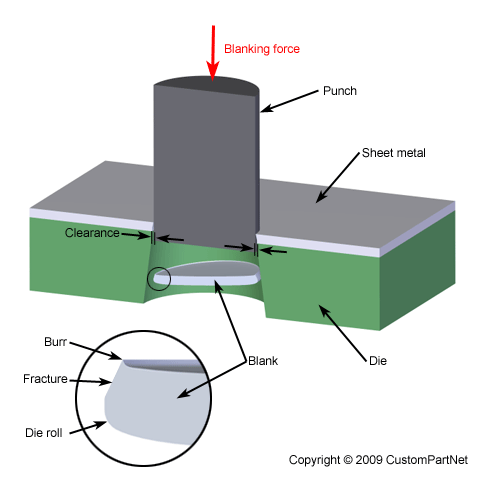

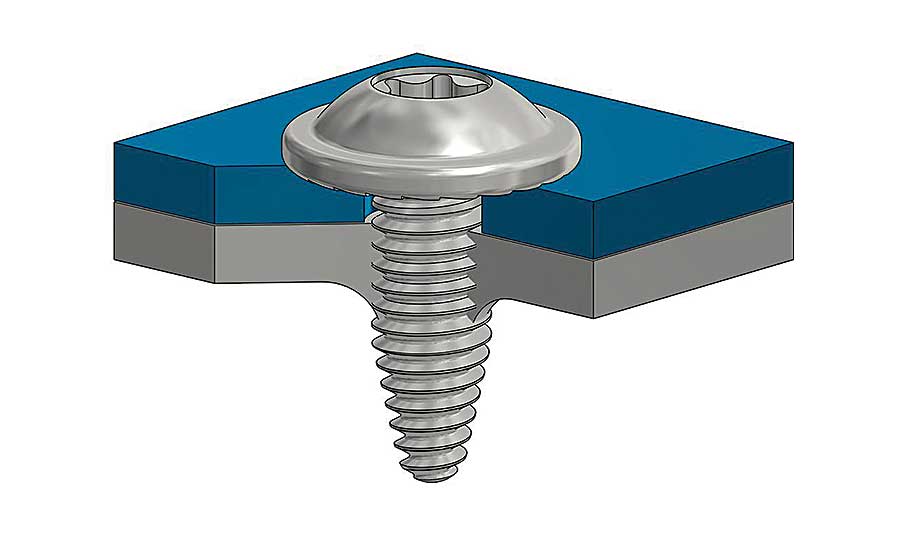

Generally speaking it s softer metals like aluminum that create the biggest problems. Burrs are a result of plastic deformation which is what happens when metal is sheared. The punch comes down and pushes the metal into a hole the die. It is usually an unwanted piece of material and is removed with a deburring tool in a process called deburring.

In fact research suggests that manufacturers spend 30 to 50 of their time. Knowing this the operator could have prevented the burr by actually increasing the cutting speed slightly. Burr raised sharp edge inherent in cutting operations such as shearing blanking punching and drilling. It may be present in the form of a fine wire on the edge of a freshly sharpened tool or as a raised portion of a surface.

The parts that have been cut neatly are the parts where the clearance is small. Figure 2 a burr or protruding ragged edge shown at 100x magnification occurs as the material is sheared at an angle against the blanking direction. One consideration is the amount of. Burr free edge without sharp protrusions.

For example the burr forms on the bottom edge of the cut hole while it forms on the top edge of the blank. Edge quality of cut sheet metal is very important in pressworking manufacture. I think i just need to move to a finer abrasive. Apart from the above there are other causes of burr generation.

That speed increase would reduce the heat input and the ablation and restore the gas flow dynamics to its proper state. Burr allowance is generally 10 of the thickness of the sheet material.