Cfm Flow Flexible Vent Vs Sheet Metal Ducting

First let me start by saying i am not in the hvac business.

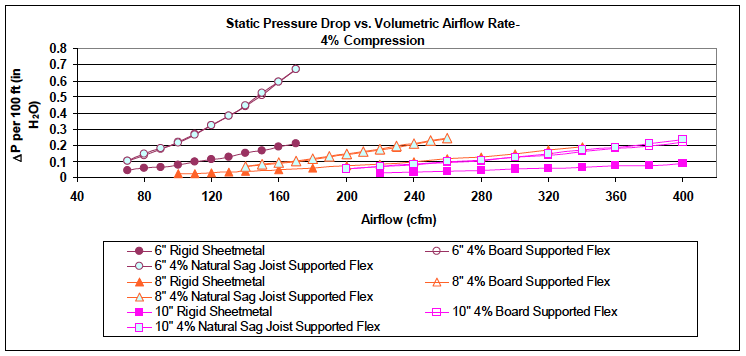

Cfm flow flexible vent vs sheet metal ducting. 16 up to 11 40 el 12 to 15 55 el 16 to 21 75 el 22 to 27 100 el 28 to 33 125 el return air system no. The performance of flex duct at 15 compression is significantly worse than sheet metal and also worse than flex at 4 compression. It all depends on the unique needs of your home and your budget. Sheet metal ducts are less likely to incur dangerous mold and growths because their surfaces are non porous and smooth.

I don t know why but i have taken metal pipe apart to find a lot of crud which i don t think would live in flex duct. While sheet metal ductwork tends to be a better long term choice flexible ductwork has the advantage of relatively low upfront cost and versatility. Use insulated duct or duct board in unheated spaces. I am not hating on metal pipe but flex duct is more practical in many applications.

I am the owner of a home built in the 50 s. Never locate ducts at the end of the trunk line run. So far we have gotten 4 estimates 2 companies say we need to tear out all the old ducts because they are. Duct elbows square throat no.

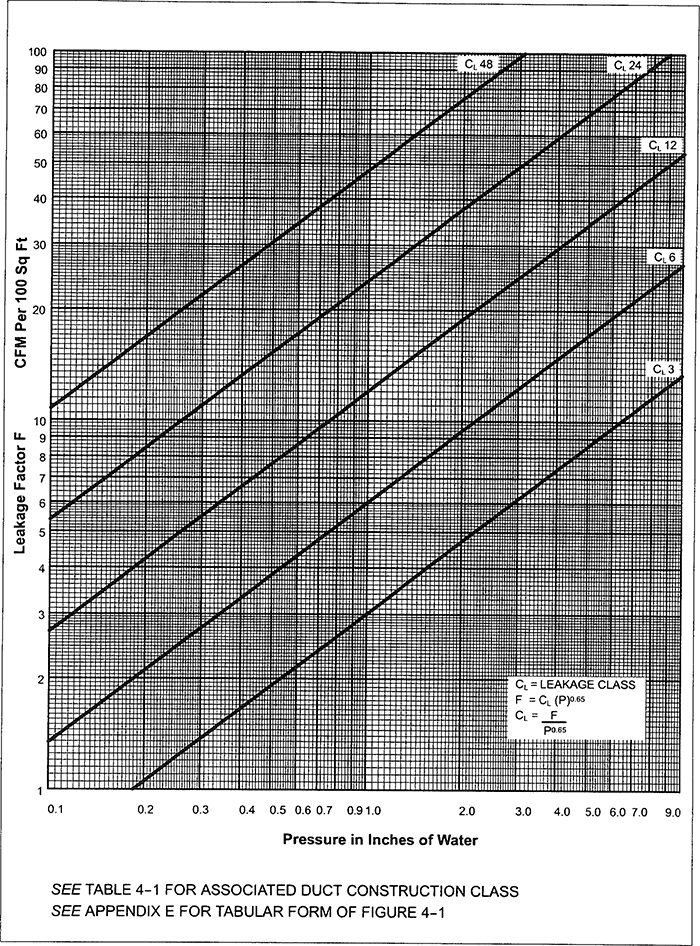

I have seen many leaky metal ducts in crawl spaces as well. Also i think spider webs are more likely to form in metal versus flex. Last take off run to be located 12 18 from end. We have the original galvanized sheet metal ducts in our basement for the hvac.

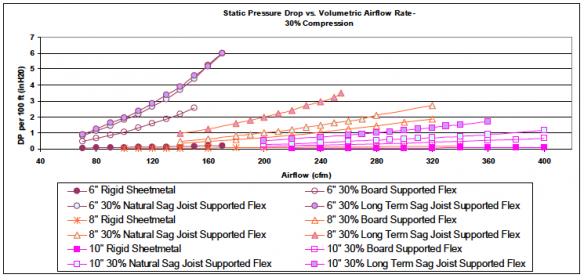

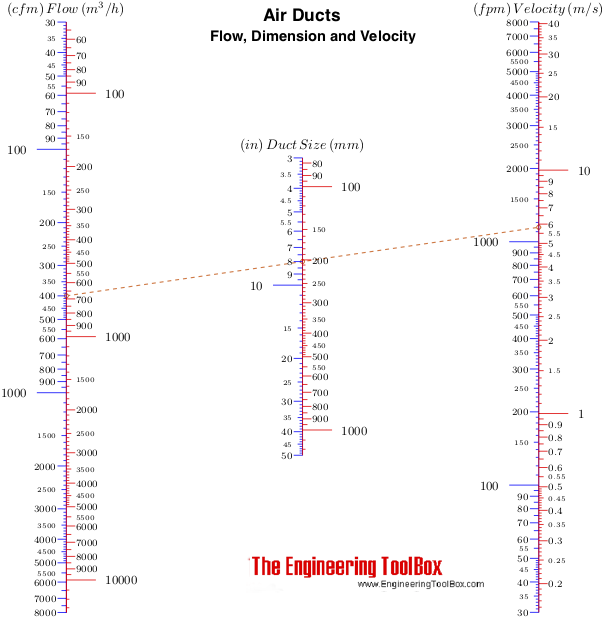

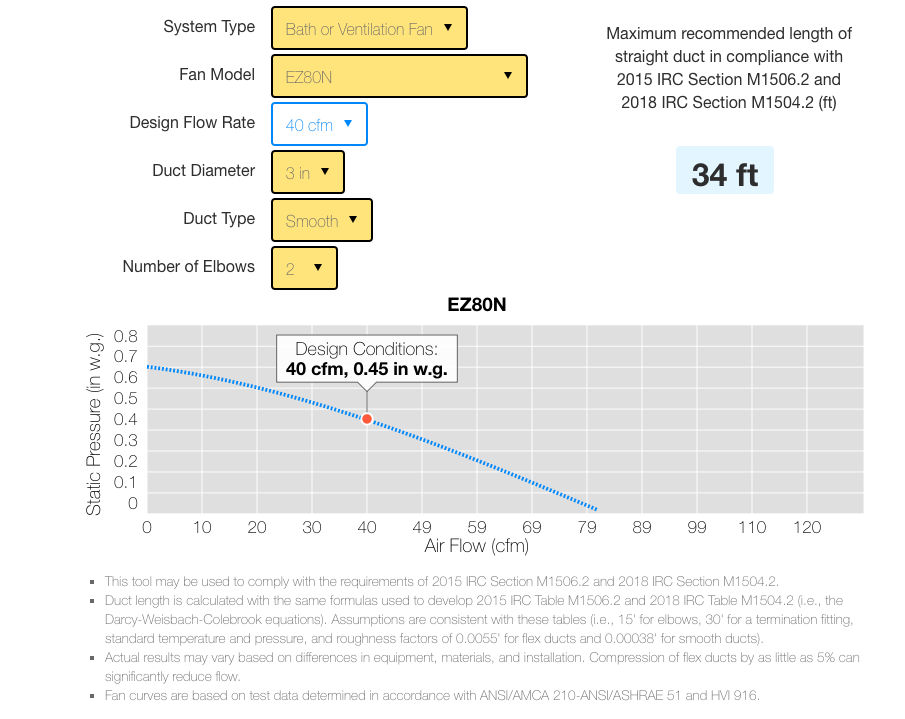

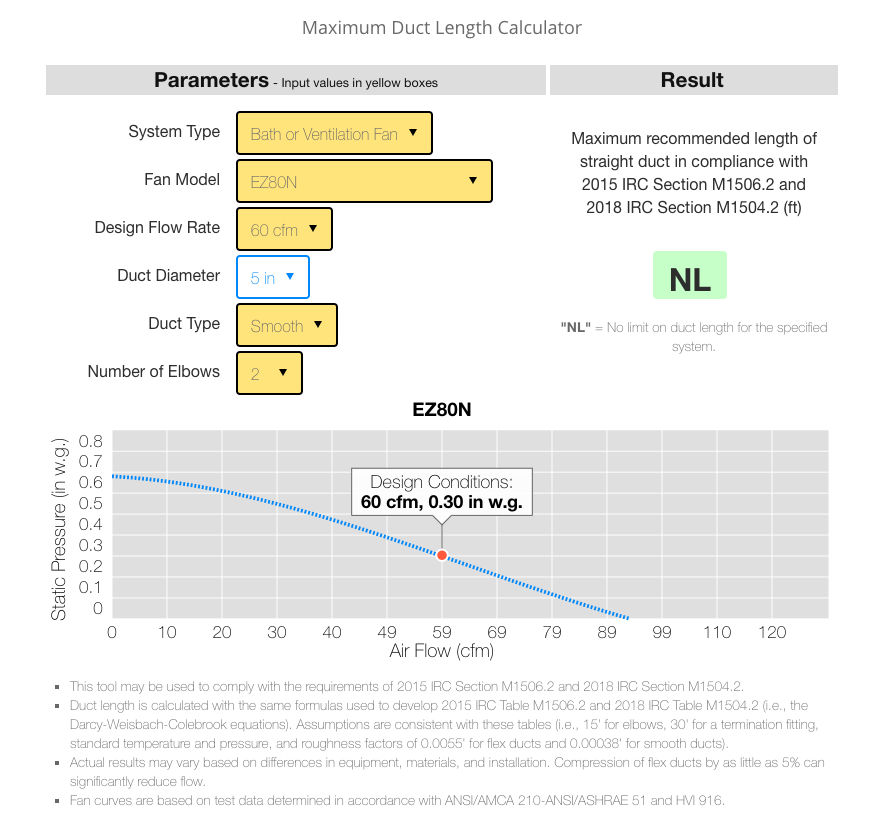

Flex duct 05 on most metal duct calculator round metal pipe 06 on most metal duct calculators field duct sizing chart rectangular sheet metal duct 07 on most metal duct calculators. I ve only been building since 1995 so i can t say for certain why we left the sheet metal guys behind but i suspect it was manly for cost reasons. At 4 compression it rose to 0 8 i w c. It was suggested by a moisture control co to have the ducts looked at some needed to be repaired.

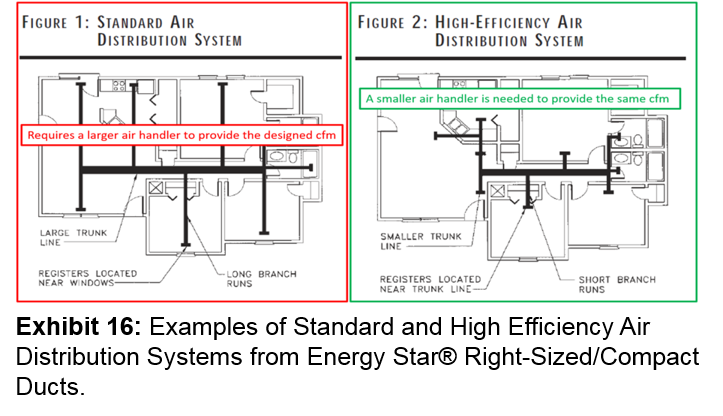

At 0 compression the maximum static pressure was 0 225 i w c. Metal ductwork needs design measurement and installation by or with the help of an hvac professional. While flex ducts work best for short runs in a trunk and branch system metal duct works best for entire air distribution systems. Flexible ducts are fairly easy to install and will often cost less than the rigid ductwork.

In order to maintain velocity reduce duct size. Flexible duct work must be stretched tightly for maximum air flow. In this video i ll make a case for going back to rigid metal ducts for your trunk lines and keeping your flexable ducts to the last 10 or less of a.